17-7 Steel Strip, Coil, Foil, Wire, AMS 5528 (CONDA), AMS 5529 (COND C), ASTM A693, MIL-S25043

Tlhaloso

Mofuta oa 17-7PH® Precipitation Hardening Alloy ke semi-austenitic stainless steel e leng austenitic ka boemo ba annealed, empa martensitic boemong bo thata.Mofuta oa 17-7PH® o fana ka matla a phahameng le ho thatafala, thepa e ntle ea mokhathala, ho hanyetsa kutu e ntle le ho sotha ho fokolang holim'a phekolo ea mocheso.E thehoa habonolo ka boemo ba annealed, ebe e thatafalloa ho matla a matla a matla ka phekolo e bonolo ea mocheso ho Maemo a RH 950 le TH 1050. Matla a phahameng a ikhethang a Condition CH 900 a fana ka melemo e mengata moo ho fokolang ductility le ho sebetsa ho lumelloang.Boemong ba eona ba kalafo ea mocheso, motsoako ona o fana ka thepa e ikhethang ea mochini mochesong o fihlang ho 900 ° F (482 ° C).

K'hemik'hale MOEKETSI

Khabone: 0.090 max

Manganese: 1.00 max

silicon: 1.00 max

Chromium: 16.00- 18.00

Nickel: 6.50- 7.75

Aluminium: 0.75-1.50

Phosphorus: 0.040 max

Sebabole: 0.030 max

Tšepe: Ho leka-lekana

LITŠOANTŠISO TŠEBELE

Boima: (Moemo. A): 0.282 lbs/in3 7.80 g/cm3

Matla a Motlakase: (microhm-cm) (maemo ohle): 60 °F (20 °C): 80

Thermal Conductivity: BTU/hr/ft2/ft/°F (W/m•K)

Ho 300 °F (149 °C): 9.5 (16.5)

Kakaretso ea Coefficient ea Katoloso ea Thermal: in/inl°F (µm/m•K): (Cond. A):

70 -200 °F (21 -93 °C): 8.5 x 10-5 (15.3)

70 -400 °F (21 -204 °C): 9.0 x 10-5 (16.2)

70 -600 °F (21 -315 °C): 9.5 x 10-5 (17.1)

70 -800 °F (21 -427 °C): 9.6 x 1 o-6 (16.0)

Modulus of Elasticity: ksi (MPa)

29 x 103 (200 x 103) ka tsitsipano

Magnetic Permeability:

Annealed: E fokolang ferromagnetic

Phekolo ea mocheso: Matla a ferromagnetic

LIPOPO

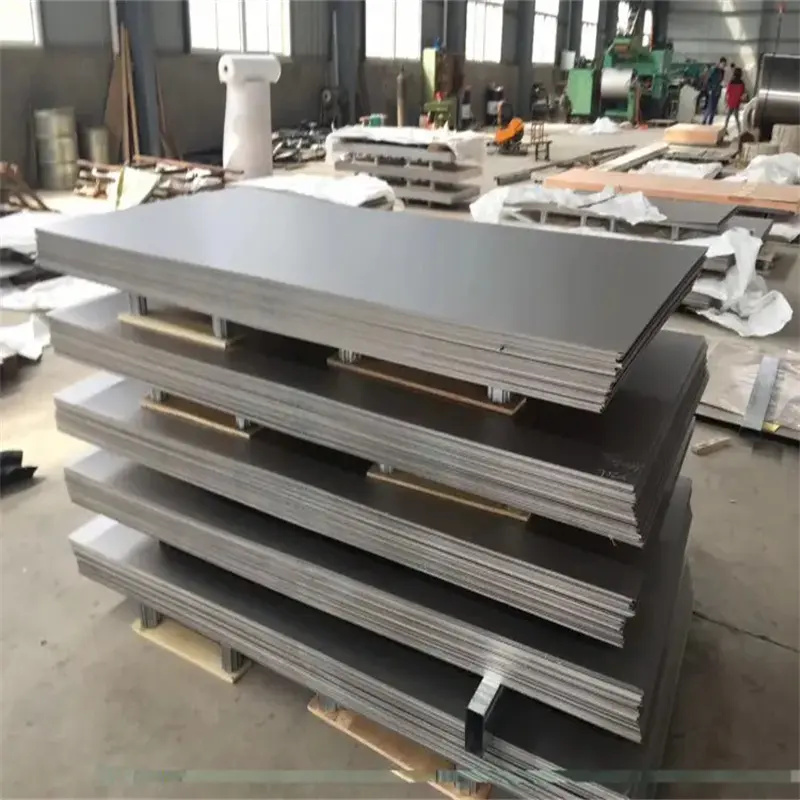

Hlakola Coil

- 17-7PH Lesela la tšepe le sa hloekang

- 17-7PH Foil ea tšepe e sa hloekang

- 17-7PH Ribone ea tšepe e sa hloekang

Lihlahisoa tsa mohala

- 17-7PH Mohala oa tšepe e sa hloekang le terata ea profil

- 17-7PH Mohala oa tšepe o se nang tšepe o pota-potileng

- 17-7PH Stainless Steel Flat Wire

- 17-7PH Stainless Steel Square Wire

Tshebetso

Ho sebetsa Mechanical Properties Ka Mocheso oa Kamore

Range ea tekanyo: <.010 inches

Matla a ho Feta Tensile: 150 KSI max (1035 MPa max)

Matla a Puno (0.2% offset): 65 KSI max (450 MPa max)

Elongation: Ikopanye le Ulbrich Technical Services

Range ea tekanyo: > .010 lisenthimithara

Matla a ho Feta Tensile: 150 KSI max (1035 MPa max)

Matla a Puno (0.2% offset): 55 KSI max (380 MPa max)

Elongation: 20% min

Ho thatafala: Rb 92 max

Maemo a Tlwaelehileng C

Matla a ho Fetisisa a Matla: 200 KSI min (1380 MPa min)

Matla a ho Hlahisa (0.2% offset): 175 KSI min (1205 MPa min)

Elongation: 1% min

Thata: Re 41 min (sepheo)

KE TLATSETSO ROLLED TEMPERS:

Ikopanye le Ulbrich Technical Services haeba ho hlokahala khalefo ntle le Boemo ba C.

PHEKO EA MOCHESO EA 17-7PH Stainless STEEL

TH 1050 Tloaelehileng

Matla a ho Fetisisa a Matla: 180 KSI min (1240 MPa min)

Matla a ho Hlahisa: (0.2% Offset) 150 KSI min (1034 MPa min)

Elongation: Ikopanye le Ulbrich Technical Services

Thata: Re 38 min

Setšoantšo sa RH950

Matla a ho Fetisisa a Matla: 210 KSI min (1450 MPa min)

Matla a ho Hlahisa: (0.2 Offset) 190 KSI min (1310 MPa min)

Elongation: Ikopanye le Ulbrich Technical Services

Thata: Re 44 min

CH900 E tloaelehileng

Matla a ho Fetisisa a Matla: 240 KSI min (1655 MPa min)

Matla a ho Hlahisa: (0.2% Offset) 230 KSI min (1586 MPa min)

Elongation: 1% min

Thata: Re 46 min (sepheo)

KEKELETSO LEFAKA

HO KHANYETSA HO KHOA HA TŠEPE EA 17-7PH

Sheba ho NACE (National Association of Corrosion Engineers) bakeng sa likhothaletso.